Iskanda

Senior Members-

Total de itens

41 -

Registro em

-

Última visita

-

Days Won

9

Tudo que Iskanda postou

-

In the meantime we start to translate the new website to English: https://xenia.coffee/en/ The 1st section (highlights) is ready and more will follow:

-

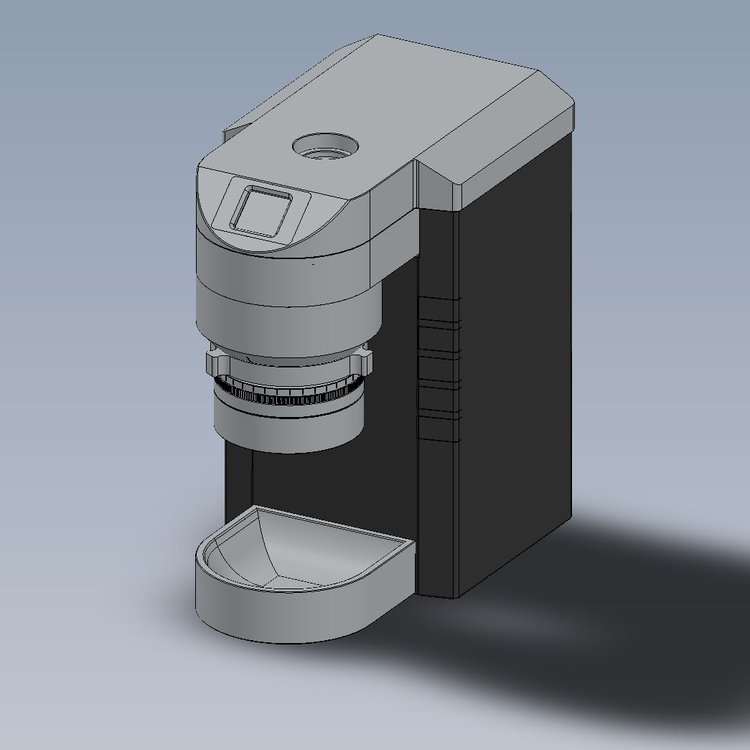

Now we work on a grinder with nearly 0-retention: And we hope to finish an upgrade for our Xenia in 2020: a machines with 2 boilers.

-

I think it is a bit late for an answer. Sorry. We have been very busy with extending the production and in the meantime we produced ~750 machines. In case of interested, you can use https://xenia.coffee/konfig-en/ to define your desired configuration. We made also some special machines, like: More images you can see here: https://www.instagram.com/xenia_espresso/ and: https://xenia.coffee/impressionen/

-

We increased in the meantime the production a bit (~2-3 machines per day) and I got some nice pictures from some customers: A unique design:

-

Here a try with a special color:

-

In case someone like to see an unboxing video of the 1st machine of the 2nd production: The comments are in German, but it should be easy to understand what is happening. Some more pictures, videos & information you can find on our new website www.xenia.coffee. Some translations needed to be updated, but there are already many English articles.

-

If you order - we send (one day) In the meantime someone was so kind and made some beautiful pictures with 2 of our machines. And here are some more :

-

In the meantime we produced a batch of machines an I can show a few pictures. Fortunatly all the machines are working without problems, even they are the 1st units

-

Thank you. It is a pleasure that we can 'play' a bit with the colors and design. It is not only simple production Btw: there is a new grinder in the market. I tested the last 3 months several grinders and among all the 860 is the best. The very best concerning the handling and consistency of the shots. The 860 is produced by Conti Valerio in Italy (Firenze). I wrote several reviews about the grinder and about the 'why' we choose the 860 (but it is in german): http://xenia.coffee/index.php/muehlen/otto-860 If you think about the grinder and can get a 860: think about it seriously.

-

Finally we started the production and for the 1st machine we choose an unusual color for the facade. Usually the faceade is ordered with "black eloxal" or "brilliant stainless steel". More pictures: https://www.facebook.com/Xenia.Espressomaschinen/photos_stream?tab=photos_albums

-

Hello, may be you can do a favour for me. We are participating in a competition for small business from Fedex and to reach the next round of the 10 companies, we need some 'shares', 'likes',..... If you want support us, you can share our profile: http://de.wettbewerb.fedex.com/Gallery/Detail/13f71e45-8de4-444a-a76f-9c1a36cf5e98 Just click here on 'anything': and share it. Thank you!

-

Actually we work on the second extension board and we can try reserve a port for it. But depending on the space, we will add free (multipurpose) ports in each case. For the final layout of the base board, we have been able to add one additional port for an external solidstaterelais (for what ever we meight need it one day). And we added 2 ports for 2 addional buttons. The advantage is that we orderrd toggle switches with 3 position: This allows us - for example - to implement 2 function for brewing: 2->3 = start the shot and wait until the user ends the shot 1<-2 = start the shot and end it after x seconds May be the challenge willl be to find the right scale.

-

The problem is 'only' that we can't deliver a machine with a software poviding such a function. But there is no patent of software and the firmware/software could be modified and may be soneome publish one day a new version and you can upload it.

-

There is a patent

-

No idea...I will read and we can think about it. As we use Solidstaterelais (with zerocrossing) we should be able to do some things by software. But often there is a patent and it will avoid it. We think to deliver the Xenia with a kind of basic software - and release the code as freeware. It meight happen that a team of developers will start implementing new feature. It will be like a 'fork'.

-

The traditional rotary pump forced the decision: tank or rotary pump. Both was not possible as the space inside the machine ist very limited. The new pumpe is a smaller and so we can offer rotary pump and water tank.

-

Annotation: The pump is a "MVP with motor 958"

-

The 24V-version is (as far as I remember) not suitable for the application. Right: a power supply would be needed, as we have 'only' 5 and 12V inside the machine. Mayxbn it is interesring for you: Yesterday we tried to assemble a special kind of measuring device to measure inside the coffee. But we don't know yet if it works. If you like to see it: https://www.facebook.com/media/set/?set=a.1679586135646178.1073741858.1612085189062940&type=3&ref=notif¬if_t=like It was not very difficulty to assemble.

-

This is true. Btw: it works: It is 230VAC. What is very big ? The pump ? Not really. At least it fits for my machine

-

It looks like we can really install the rotationpump with the tank. The new pump is comsuming less space:

-

Thank you very much It was also a pleasure for me to assemble it and before I started it I made all unpleasant work - just to have a free mind. This morning I finished it and can start testing. It is very close to the final 'design': Only some improvements are needed.

-

Well, my day is finished. I tried to assemble a 2nd machine to use it the next 4 days on the anual meeting of a choir in middle germany (my wife is participating) and I was allowed to dispense Espresso and Cappucchino. But it took too long to find a good setting for the cables (at least more beautiful than in the past) and I was not able to finish and test the machine. May be it is usful to think about the colors, but this will be not my duty. The signal lights (LEDs). In the middle: the control board installed in a kind of channel which protects the board against the heat. There are long holes to the bottom and top to allow air flow. Toggle switches and LEDs: Pressostat (upper left, black cable) Level probe boiler (middle/purple cable) brewgroup thermostat (red cable) and heating catridges 2x150 Watt (blue cable) control unit with more cables: boiler heating (black/red cable) 3 way valve before the HX (blue cable) to the middle left: the fitting to connect to the HX ce The central "on/off" with a fuse (not installed yet) security thermostat (blue cable) to the upper left: security valve and behind: thermostat (red cable) and heating of the brewgroup (blue cable) to the lower left: exit of the HX and connection (pipe) to the brewgroup. Connection to the circuit (lower right corner): Tomorrow we get hopfully the new rotary pump before we leave our place - else I will install the vibration pump TP600 from ODE. Good night

-

This is not easy to set up. One very very big challenge is to find all partners to produce the parts in the rigth way. It was a kind of nightmare as many many people think that their company is the best in world and can do anything at the best quality. After some weeks or even month you find out that there is a lack of knowledge, machine, raw material,.... And I think as we are too small: it will get out of control. As we love to travel and see other counties and people: we prefer to choose some country and can visit them to start the business running with a local partner. I agree (at least about what google translated). We actually to to come to teh 1st production of 50 maschines. It was scheduled for february/march but teh manufacturer of the glas tanks 'forgot' the production. They will tell me a date in ~2 weeks. As to me...it will take 8-10 weeks until we deliver the 1st machines. If it works and the customers are satiefied - we prepare the next production. This could be june/july/august. If it don't works...time to go back to IT-business